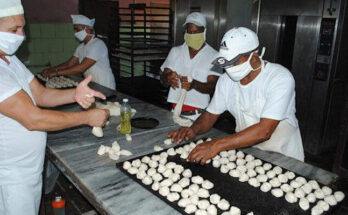

Electrical engineer Miguel Vega Ciudad is one of the more than 700 aniristas who make up the movement of innovators and rationalizers of the Santiago municipality of Contramaestre. Vega Ciudad currently works as a maintenance specialist and brigade chief at the Baire animal feed factory.

A Contramaestrian who, together with his team, contributes research with a high impact on the vitality and operation of the industry in which he works.

The manufacture of a stockpiling base equal to the industrial model made with some modifications focused the innovation of this engineer and his brigade, which is made up of ten workers.

These changes made it possible to give robustness and strength to this equipment, according to the anirist: “If the original ones lasted more than sixty years installed and in operation, we consider that these will last the same amount of time. Here we have used recovered and warehouse material for the manufacture of the piece. The innovation according to Vega Ciudad allows for better strength and better lubrication.”

This innovation will be one of the two that will represent the southeastern territory at the National Forum of Innovators and Rationalizers. Work that according to the specialist has had a saving to the country of two thousand dollars in terms of its cost, – the engineer pointed out-, and in the period of sixteen months in production around twenty seven million pesos in profits and in terms of the contribution to the state almost one million pesos, he added.

The engineer, who has had the support and collaboration of a work team, reveals: “I am not going to take all the credit for the innovation, I am representing a work in which four people participate, but really the ten colleagues who make up the brigade are workers who contribute a lot to innovation and production so that it does not stop (…)”.

Innovators who do not stop and make other contributions to the important industry. At the moment, said Miguel Vega, we are working on modifications to the bagging weight of the feed mill, replacing the filling, weighing and unloading part. It had a pneumatic system based on small cylinders that opened and closed gates. Now we are eliminating and adapting a single gate for filling with a single cylinder.

Innovators who do not stop and make other contributions to the important industry. At the moment, said Miguel Vega, we are working on modifications to the bagging weight of the feed mill, replacing the filling, weighing and unloading part. It had a pneumatic system based on small cylinders that opened and closed gates. Now we are eliminating and adapting a single gate for filling with a single cylinder.